PDX Airport

We had the pleasure of being a part of one of the largest renovation projects in Portland’s history. While working for Superfab.co, we were able to craft an engaging environment for visitors.

-

Strategy

Sustainability, Ethical Forestry

-

Design

Planning, Fabrication, and Install

-

Client

PDX Airport

-

Partners

Superfab, ZGF Architects, Timberlab, Hoffman Skanska,

-

Tags

Airport, Hoffman, installation, millwork, PDX, Port of Portland, Skanska, Superfab, Timberlab

The Portland Airport's expansion features a 9-acre, sustainable mass timber roof, showcasing Oregon's innovation and supporting local economies.

Project Overview

The PDX Airport Main Terminal expansion, a milestone in mass timber design, features a 9-acre roof constructed from 3.5 million board feet of locally sourced wood. This project supports local economies, incorporating contributions from small family-owned forests, non-profits, and tribal nations. Designed by architects at ZGF, it exemplifies Oregon’s deep-rooted tradition of forest product innovation.

The roof includes forty-nine skylights that filter natural light into sixty percent of the terminal, crafted from mass plywood panels, glulam beams, and timber lattice. This intricate structure highlights traditional indigenous weaving techniques, reducing the reliance on steel and contributing to the terminal’s sustainability. The project represents a blend of cost-effectiveness, constructability, and a celebration of the Pacific Northwest’s timber industry.

PDX not only stands as a testament to modern engineering prowess and sustainable practices but also embodies a harmonious blend of the region’s historic relationship with its forests and its forward-thinking approach to architectural design.

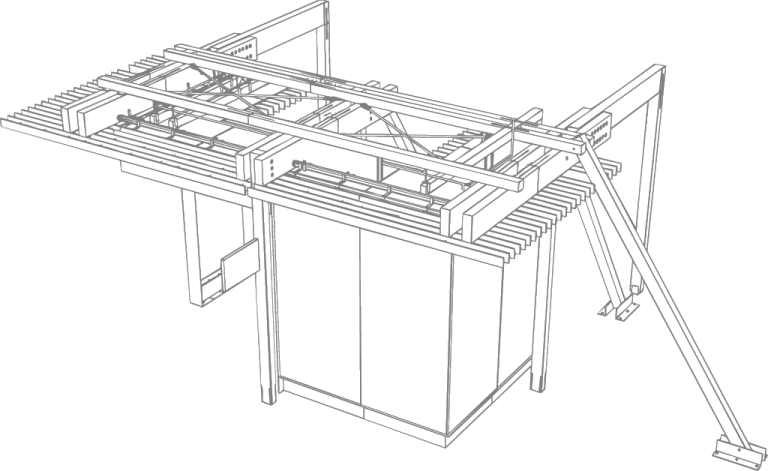

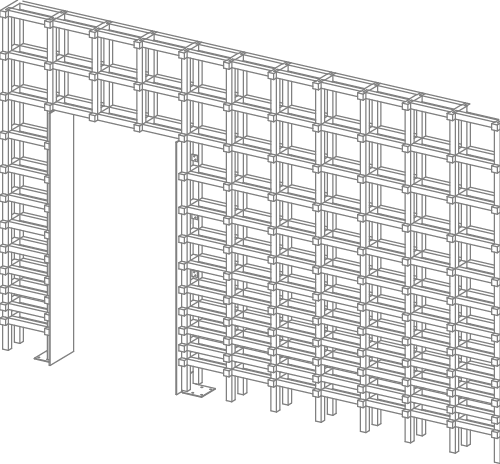

Full-Scale Mockups

We were able to utilize the nearby cargo warehouse to build a few freestanding full-scale mockups of ZGF’s designs.

Our mockups included a working model of one automated bathroom stall.

A complete freestanding concessions model with complete fire package, security screens, glazing, and timber framing.

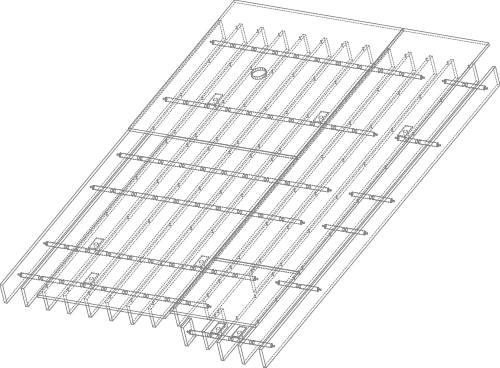

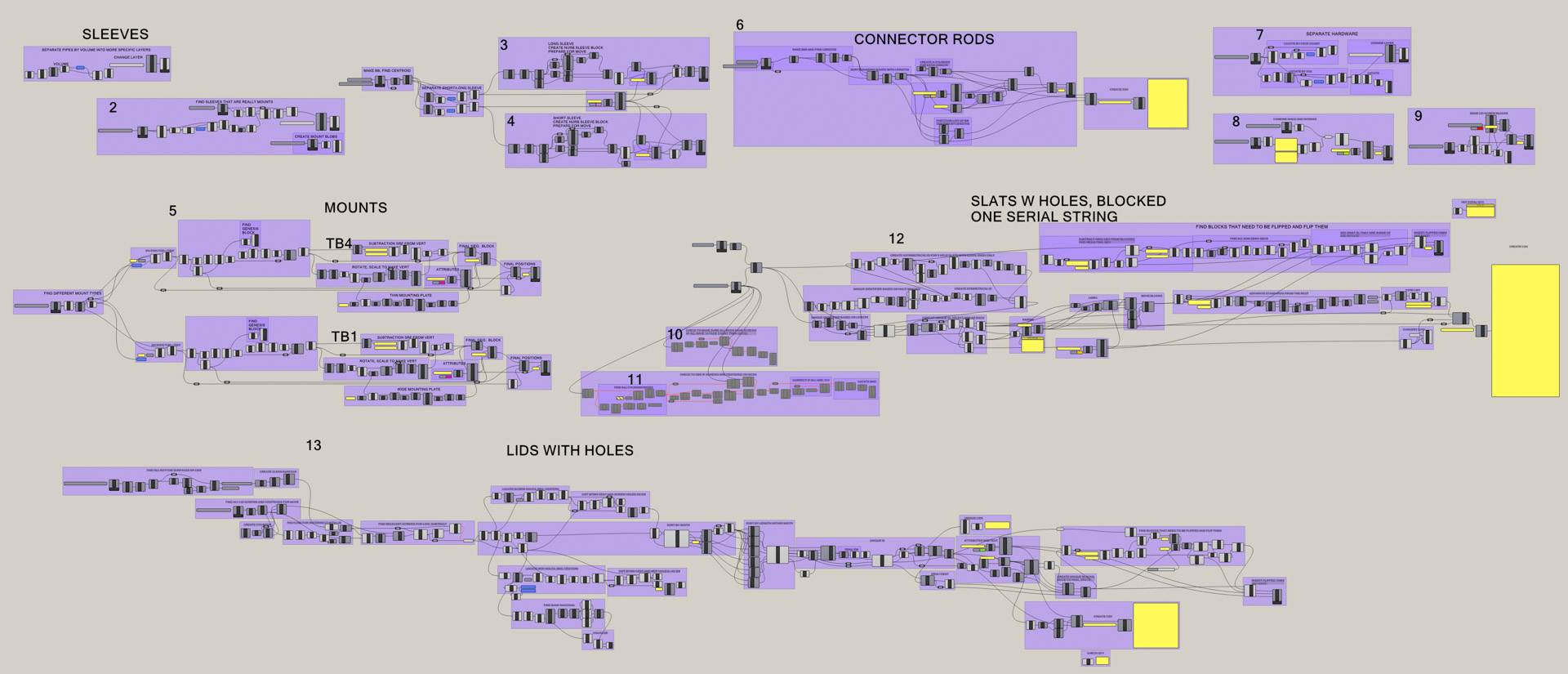

Concession Grilles

The grilles presented significant complexity, primarily due to the unique challenges posed by the MEP and fire systems for each ceiling section.

By combining detailed plans with specific cutlists for each ceiling section, Superfab ensured the accurate and seamless installation of the grilles, contributing to the project’s overall success. This meticulous process not only highlighted Superfab’s commitment to precision and sustainability but also demonstrated the power of leveraging advanced design tools.

Overcoming Obstacles

Superfab’s lead designer on the grille’s project, Alex Diamond, ingeniously addressed challenges by developing a robust script using Rhino’s Grasshopper suite. This innovative approach allowed the team to organize the intricate designs effectively, reducing material waste and enhancing efficiency. By combining detailed plans with specific cutlists for each ceiling section, Superfab ensured the accurate and seamless installation of the grilles, contributing to the project’s overall success.

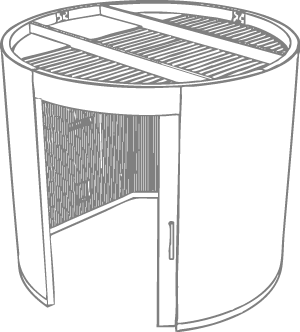

Screening Rooms

The screening rooms is where I focused most of my attention to this project.

Each cylindrical room consisted of roughly 300 milled 2×4’s, each given an “angled acoustic profile” which helped reduce echo in the room and allowed each to connect into a cylinder.

While on paper he idea seemed straightforward, in practice, it was incredibly difficult as compounding tolerances created many issues.

Seam Wall

Each stick of Doug fir had to be milled in three parts. Each part utilizing a separate CNC jig. The “spanners” required a custom fixture for Superfab’s 4×4 CNC.

Utilizing each of these in succession allowed us to maintain constant milling and meet our target deadline.

Got a project?

We’re a small team of skilled creatives passionate about bringing unique ideas to life. Whether your vision is big or small, we take pride in collaborating to turn your dreams into reality.

If you’re ready to start your next project or simply want to discuss your ideas, we’d love to hear from you! Contact us today to explore how we can bring your vision to life together.